Discover the power and precision of our 2000W Fiber Handheld Laser, offering advanced cleaning and welding capabilities for a variety of industrial applications. Whether you need to restore surfaces or create high-quality welds, this versatile tool delivers superior performance.

Our 2000W Fiber Handheld Laser is a highly effective cleaning tool, capable of removing rust, paint, and contaminants from metal surfaces with precision. While laser cleaning can create some dust from the vaporized materials, it offers a more controlled and environmentally friendly option for surface restoration.

Laser cleaning works by directing a powerful laser beam onto the surface, heating and vaporizing unwanted layers such as rust or paint.

This method ensures that the base material is left intact, offering a non-abrasive cleaning process that can be fine-tuned depending on the surface being treated.

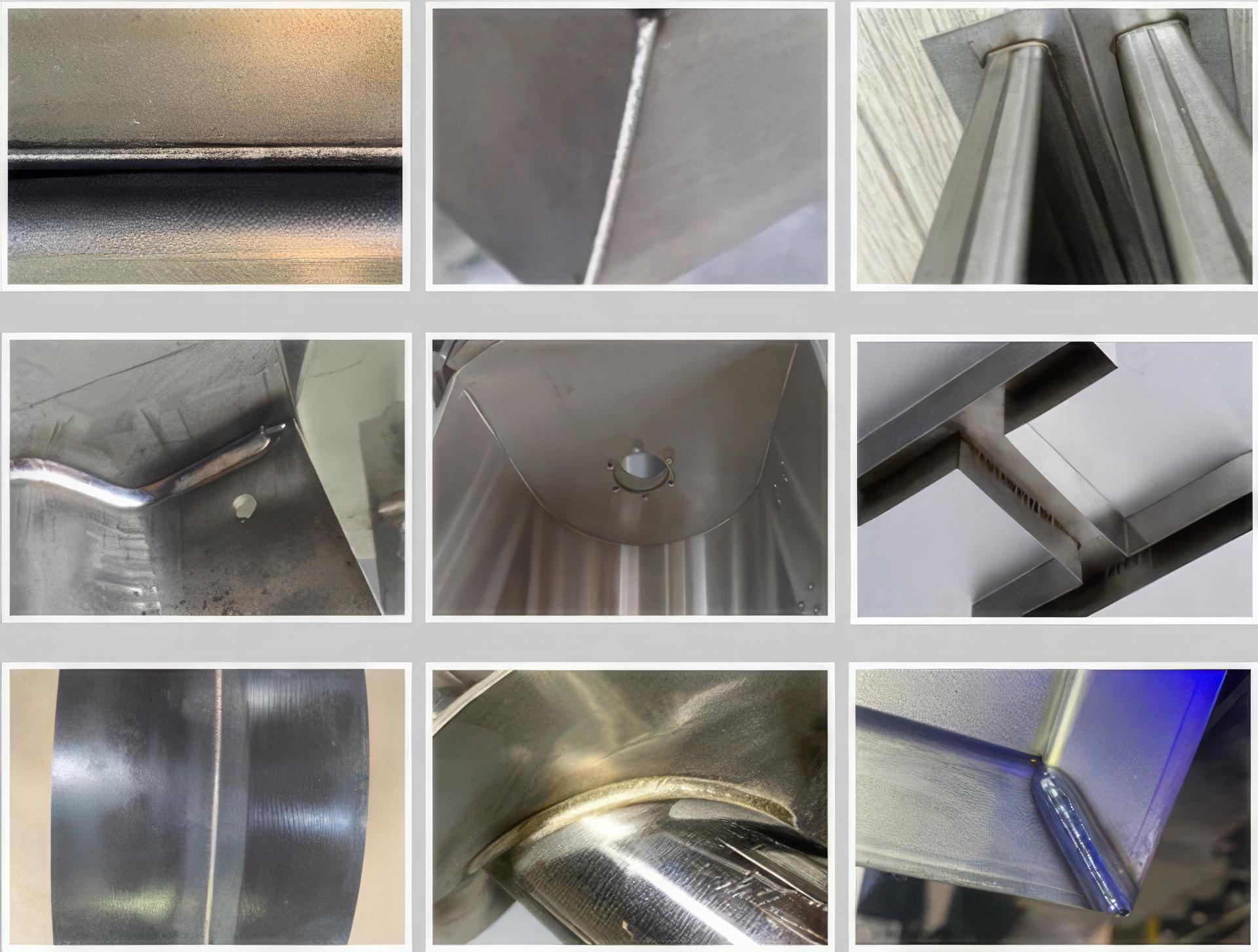

Our 2000W Fiber Handheld Laser also doubles as a powerful welding tool. Laser welding creates high-quality, precise welds in metals, including stainless steel, aluminum, and titanium. It’s used in industries requiring strong and visually appealing welds, such as automotive, aerospace, and metal fabrication.

Laser welding operates by directing a high-intensity laser beam at the joint of two materials. The laser melts the metal, creating a small and controlled weld pool. This allows for deep penetration and precise weld seams, making it ideal for both small intricate parts and larger metal structures.